The Advantages of Fiber Laser Cutting for Metal Fabrication in Calgary, Alberta

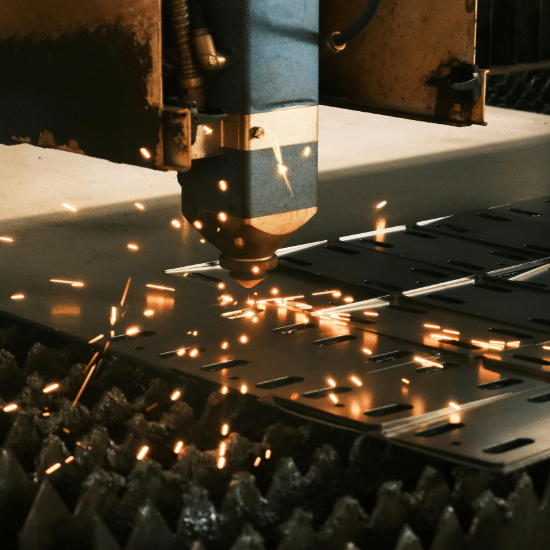

Calgary’s manufacturing, construction, and energy sectors demand precision, reliability, and fast turnaround times. As local industries continue to evolve, fiber laser cutting has become a critical technology for modern metal fabrication in Calgary, Alberta. From high-volume industrial components to specialized one-off parts, fiber lasers provide unmatched accuracy, efficiency, and versatility.

Precision Metal Fabrication for Calgary Industries

One of the primary advantages of fiber laser cutting is its exceptional precision. A modern laser cutter can achieve tight tolerances and complex geometries that traditional metal cutting methods struggle to replicate. This level of accuracy is essential for Calgary-based industries such as oil and gas, construction, agriculture, and manufacturing, where components must meet exact specifications.For companies offering custom metal fabrication in Calgary, fiber laser technology allows for intricate designs, clean cuts, and consistent quality—whether producing prototypes or full production runs.

Faster Turnaround Times and Local Production Efficiency

Speed is a major advantage of fiber laser cutting, especially for Calgary manufacturers working on tight schedules or responding to urgent project demands. Fiber lasers cut thin to medium-gauge metals significantly faster than plasma or mechanical cutting systems, helping local fabrication shops reduce lead times and increase throughput.

By improving productivity, Calgary metal fabricators can keep projects on schedule while maintaining high-quality standards.

Superior Stainless Steel and Aluminum Fabrication

Fiber lasers are especially effective for stainless steel fabrication and aluminum fabrication, both widely used across Calgary’s industrial landscape. Stainless steel components benefit from smooth, oxide-free edges that often eliminate the need for secondary finishing. Aluminum—known for its reflectivity—is cut cleanly and efficiently using fiber laser technology.

These advantages are critical for applications requiring corrosion resistance, lightweight strength, and a clean finished appearance.

Lower Costs and Reduced Maintenance

For Calgary metal fabrication shops, controlling operating costs is essential. Fiber laser cutting systems are highly energy-efficient and require minimal maintenance due to fewer consumable parts. There are no mirrors to align or laser gases to replace, which translates into less downtime and lower long-term expenses.

Ideal for Custom Metal Fabrication in Calgary

From architectural panels to industrial brackets and machine components, fiber laser cutting offers unmatched flexibility. A single laser cutter can handle a wide range of materials, thicknesses, and designs, making it ideal for custom metal fabrication projects throughout Calgary and Southern Alberta.

Design changes can be implemented quickly, allowing fabricators to adapt to evolving project requirements without lengthy setup times.

Conclusion

Fiber laser cutting has become a cornerstone of modern metal fabrication in Calgary, delivering precision, speed, and cost-efficiency. Whether for stainless steel fabrication, aluminum fabrication, or specialized custom metal fabrication, fiber laser technology helps Calgary businesses stay competitive while meeting the highest quality standards.

Laser Cutting at Aaron Machine Shop

Aaron Machine Shop recently purchased a new 6KW state-of-the-art fiber laser cutting table. The addition of a fiber laser cutting machine allows Aaron Machine Shop to reduce cut times and improve accuracy, particularly for thinner metal material. This will improve pricing competitiveness and turnaround times for Aaron Machine Shop customers. Send us a request for quote today, Aaron Machine Shop is able to cut all metal materials with our new laser cutting table!

Share this article

The Most Common Materials Used in Metal Fabrication

Metal fabrication plays a crucial role in building a wide variety of products, such as…

An Overview of the CNC Machining Process

Computer-numerical control (CNC) machining is highly important in the manufacturing industry. Equipment such as shaping…

Importance of Welding Services for Metal Buildings

Welding is the most durable and strongest method to join two separate pieces of metal…